Adjustments and Modifications — Step by Step to a Customized Horseshoe

At this point, we would like to provide you with a brief overview of how you can optimally adjust our horseshoes to fit the hoof. Of course, this also includes possible modifications such as removing the quarter clips or grinding a deeper tread pattern.

Most of the information on this page applies to both our composite horseshoes and the pure plastic models.

With its metal inlay, the composite horseshoe offers protection and support for the coffin bone and, at the same time, flexibility and shock absorption for the inner soft tissue structure, tendons and ligaments.

With four different shapes (round / oval / STS / open-toed) and sizes in 4mm steps (8mm steps from size 182mm on), there is a perfect horseshoe available for (almost) every horse.

However, in order for the hoof to optimally benefit from the functionality of the horseshoe and to make sure the horseshoe doesn't get lost during the regular shoeing period, it is necessary to adjust the horseshoe to the hoof shape before shoeing.

Take a look at our "Accessories" category if the modifications presented here are not sufficient and the horseshoe simply won't fit properly. In cases where you need to widen the shoe laterally or extend it backward, we recommend our extensions. Additionally, modifying an open sole area into a closed one is possible. For further details, refer to our Accessories section, where we also offer wedges for adjusting the hoof angle.

Choosing Model, Shape, and Size

First, select the horseshoe that best suits your needs. Depending on whether you're planning a long trail ride with your horse or participating in eventing tournaments, you'll naturally have different requirements for the ideal horseshoe. If you're unsure which composite horseshoe is best for your horse and your discipline, feel free to reach out — we're happy to assist you.

Choosing the Right Shape

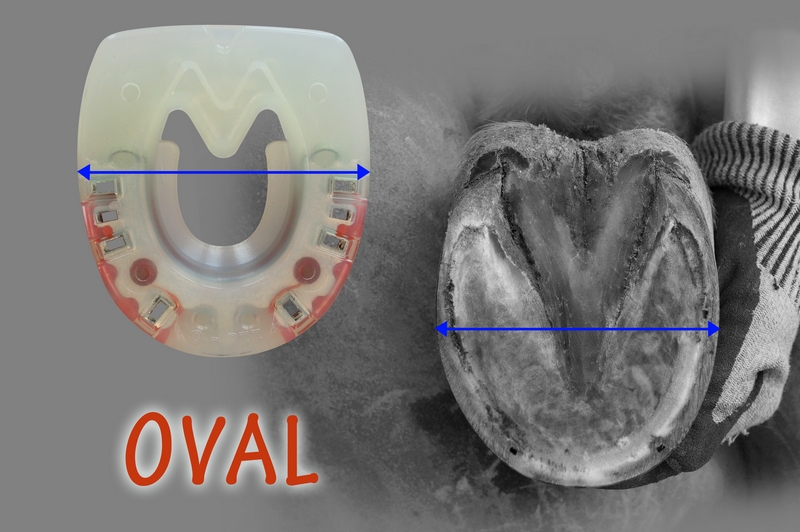

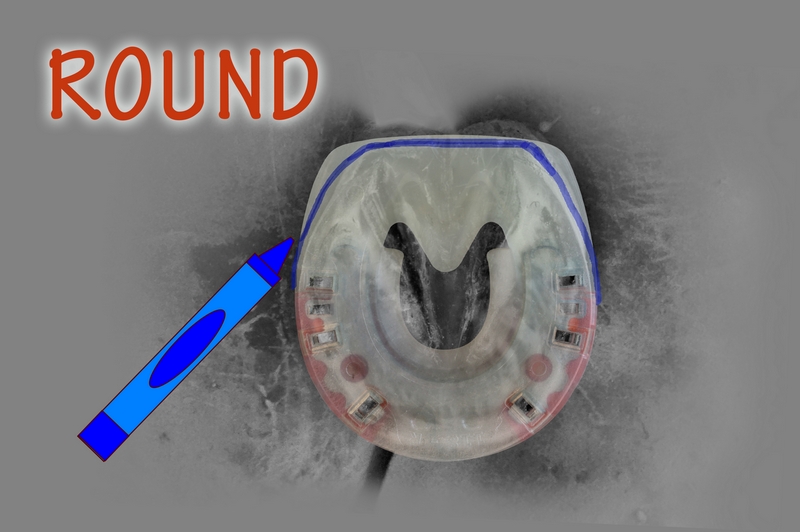

Usually, you need round horseshoes for the front hooves and oval ones for the hind hooves.

But, as always, there are exceptions.

The decision for or against an STS model, however, isn't only based on the hoof shape but

also on the locomotor mechanics of the horse. With the straighter toe area, you can

position the horseshoe slightly towards the heels and facilitate breakover.

Choosing the Right Size

The horseshoe size indicated always tells the width of the horseshoe in millimeters.

Currently, our horseshoes are available from 50mm to 198mm depending on the model. The

smallest sizes are only available as pony shoes without a metal core; the largest horseshoes

are from our Heavy Duty range, which is designed for breeds such as draft horses.

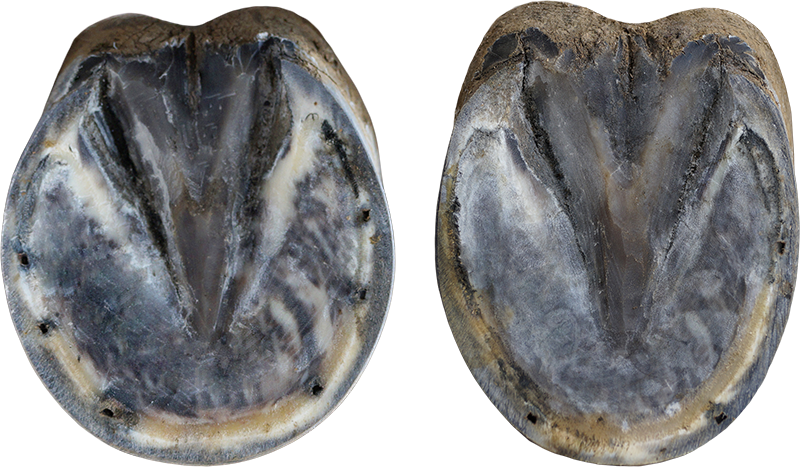

In order to determine the right size for your horse, use a measuring tape or a ruler to

measure the widest part of the newly trimmed hoof's bottom side - usually, it can be found

at a short distance behind the frog apex.

The marking indicates the widest point of the hind hoof and the oval horseshoe.

Special Case: Composite Horseshoes with Threaded Holes for Studs

When choosing the correct shape and size of a horseshoe with stud holes, attention must

always be paid to the position of the threaded inserts.

If the stud holes are placed too far in the back, the horseshoe won't fit perfectly and

the risk of losing it increases. In general, a wrong position of the thread inserts does not

only increase the risk of losing the horseshoe but also the risk that the studs cause

indesirable pressure on sensitive areas of the hoof which can cause bruising or soreness.

The correct position for thread inserts is in the heel area.

The marking shows the position of the stud holes on the hoof.

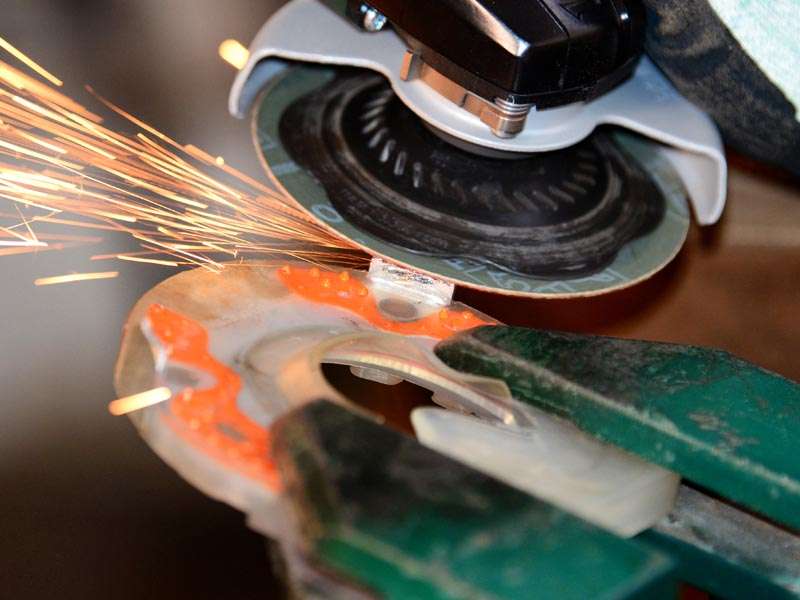

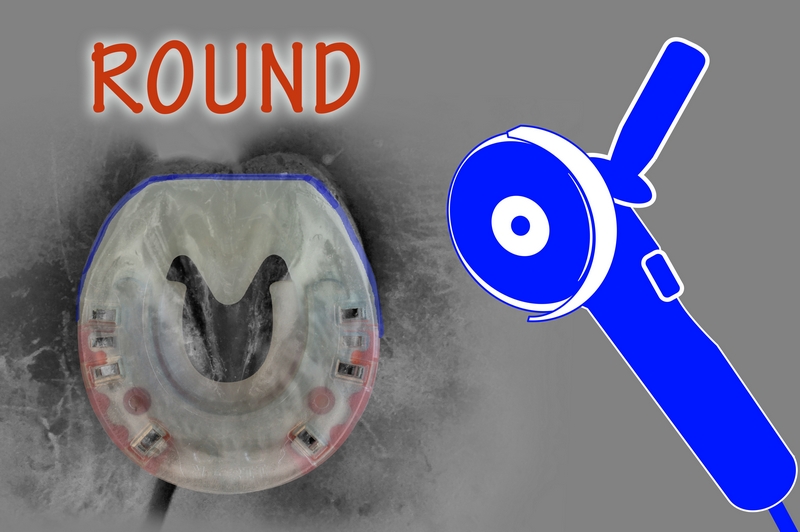

Special Case: Removal of Quarter Clips

Most of our composite horseshoes have quarter clips that you can easily remove as needed.

You can use your standard angle grinder. We recommend removing the clips

piece by piece and in turns because of the heat that develops and causes the synthetic

material to melt. Take into account the safety risk due to potential sparks. Try to preserve

as many knobs as possible! You can also partly remove the metal on the bottom side of the

horseshoe if you'd like to round the shoe off.

If you plan to use the horseshoe as an adhesive shoe, please note that you will not achieve

a plastic weld in the area of the removed quarter clips.

Grinding the quarter clips of the horseshoe.

Customizing the Horseshoe to the Individual Shape of the Horse's Hoof

We have noticed that our horseshoes are often chosen solely based on their width, and users do not consider necessary adaptations or modifications, especially in the heel area. That may work out in many cases. However, if a horseshoe isn't properly shaped to the hoof, the risk of loss and injuries increases — not only for your own horse but for the complete herd! The nails and possible quarter clips of a lost horseshoe (never mind whether it's a composite horseshoe or a conventional steel shoe) can cause severe injuries. In addition, a lost horseshoe can always take a part of the hoof wall with it.

Thus, we would like to address the precise adaptation of the shoe to the horse's hoof at this point, including all optional modifications as well as small tips and tricks that can be implemented without additional accessories.

Adjust the Horseshoe to the Hoof

Even if the selected shoe size seems to fit well at first glance, it is still necessary to adapt the shoe optimally to the individual hoof; this applies equally to pure plastic shoes as well as composite horseshoes.

The individual customization of the horseshoe is always at the discretion of the on-site

farrier.

We recommend always taking a careful look at the overall fit of the horseshoe and adjusting

the horseshoe, where necessary, to the shape of the hoof using an angle or belt grinder.

Following this, additional adjustments and optional modifications can be made.

The graphic shows to which extent you can usually modify the composite horseshoe without affecting its functionality. However, there are exceptions to this as well.

Marking the hoof shape on the horseshoe.

Customized horseshoe.

Check and Adjust the Position of the Knob Arrays

Except for the open-toed horseshoes and the pony shoes, all our horseshoes feature

integrated knob arrays. The 'Nailless' and the pure plastic model 'Classic' have soft,

production-induced knobs, while the remaining horseshoes feature a colored knob array inlay.

In case of sensitive horses with irregularly shaped or very flat hooves, we recommend

removing the inner knobs so they won't exert pressure on the sole. If you intend to glue on

the horseshoe, we generally advise removing all knobs. If you intend to use the

horseshoe as a wedge shoe, you will find additional information regarding the knobs in the

product description of the wedges.

Horseshoe after the knobs have been removed.

Adjust the Debris Guard

(Optional Modification)

Most of our horseshoes have a molded synthetic rim, also known as debris guard, which

considerably reduces the accumulation of snow, sand, and debris.

Some horses have very flat hooves and are extremely sensitive, so adjusting the debris guard

may be necessary. In this case, we recommend trying to grind the guard thinner instead

of completely cutting it out, so that its basic function can be preserved.

Modifying the debris guard of the horseshoe.

Shaping a Horseshoe More or Less Wide

(Optional Modification)

You can also change the width of the horseshoe at your own discretion. In order to make it

wider, you put it either

on a small parallel vise with a narrow or narrow-ground jaw or – if the horseshoe is small

enough – on a pair of pincers.

You can make a large horseshoe less wide with your hammer. Be careful not to twist the metal

core! If necessary, you can straighten the metal core with some well-directed hammer blows.

Original horseshoe and modified, narrower version.

Original horseshoe and modified, wider version.

Horseshoe with Deeper Tread Pattern

(Optional Modification)

Use your angle grinder with a coarse-grained grinding disk to make a profiled horseshoe from

a regular version without deeper tread pattern. Make sure the ground-off synthetic material

doesn't clog the nail holes.

For the Straight Bar horseshoes, we advise against grinding a profile afterward.

Grinding a deeper tread pattern into the plastic coating of the composite shoe.

Toe Rocker — Early Breakover

(Optional Modification)

There are different ways of creating a toe rocker on a composite horseshoe. For example, you

can treat the shoe with your angle grinder.

Another option, although not commonly utilized, is to modify the toe rocker by bending it.

Fixate the horseshoe at the edge of the anvil or in a parallel vise and reshape it with your

hammer.

If you want to position the horseshoe a little further backwards to achieve an earlier

breakover point, our STS shoes could be a possible alternative for you. The STS models are

available in a round shape with a straight toe and already have a certain rocked toe.

Modifying the horseshoe with the belt grinder.

Modifying the Synthetic Bar

(Optional Modification)

Basically, the bar's purpose is to maintain the frog's health by providing it with constant

ground contact. With a healthy, functional frog, we recommend not removing the synthetic bar

from the

horseshoe. The situation is different, for example, in case of thrush: Some farriers raise

concerns over shoeing thrush horses with composite shoes because they are closed over the

frog and

don't let fresh air circulate in the problematic area.

In particular in case of thrush it can be helpful, to modify the horseshoe in such a way

that there is a free space at the central groove and the posterior part of the collateral

grooves so you can medicate them correctly.

The extent of the modification in the frog area should be based on the severity of the

condition of the frog.

If, for example, in the case of thrush, there is already no contact between frog and the

ground even without a

horseshoe due to the severity of the thrush, it is advisable to completely remove the

plastic bar so that the frog can be regularly treated. Generally, it is possible to remove

the bar without affecting the stability of the composite horseshoe. If there is a deep

central sulcus but the frog still maintains ground contact overall, we often like to cut a

small triangle out of the bar. This allows the owner to regularly maintain the horse's frog.

Horseshoe that has been modified above the central groove.

Removing the plastic bar of the composite shoe.

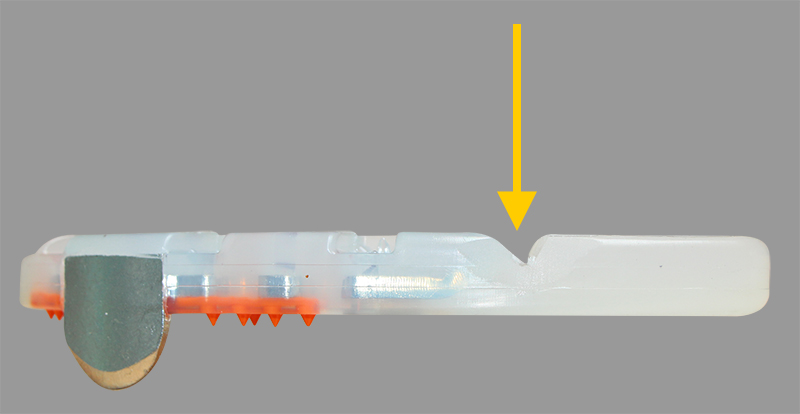

Adding a Bevel

After having shaped the horseshoe, it's time for the finishing touches: adding a bevel to the

upper and lower border of the horseshoe.

With a bevel on the hoof side as well as on the bottom side, the horseshoes will glide off

each other more easily if the horse steps on the front shoes with its hind hooves.

Bevel on the upper and lower border of the shoe.

Adding an Additional Protection against Forging

(Optional Modification)

If your horse makes large steps with its hind legs and is (despite all adjustments) prone to

forging, you can add an additional protection against forging on the bottom side of the

horseshoe. Thanks to the additional incision in the heel area, the shoe gives way more

easily and it is less likely for the horse to pull the shoe off.

In case of a Straight Bar horseshoe with a stable crossbar, this modification is not

possible.

Adding an additional protection against forging.

Protection against forging.

Shoeing Composite and Pure Plastic Horseshoes — Further Information

Above all, the question arises about the right model. In our range, you will find many different composite horseshoes with various additional features as well as pure plastic shoes.

The first step is to find the right size and shape for each horse's hoof. On the 'Sizes and Shapes' page, you'll find a template as well as a table with the measurements of our horseshoes.

The composite shoes can be applied either by nailing or gluing them to the hoof. They can also be used as cast shoes. There is a shoeing instruction available for all three of them.

The durability of the composite shoe is influenced by many factors. We have summarized the most important information regarding wear and longevity for you.

Latest Update: 2024-02-01